- Coupling

- Industrial Pulley

- Sprocket Chain Wheel

- Gear and Spares

- Metal Chain

- Conveyor Pulleys

- Conveyor Belt

- Roller Chain

- Chain Sprocket

- Industrial Coupling

- Conveyor Component

- Plummer Block

- Worm Gearbox

- Industrial Belts

- Fenner Belt

- Conveyor Chain

- Full Flexible Gear Coupling

- V Groove Pulley

- Rack and Pinion

- Flexible Coupling

- Worm Gear and Shaft

- Rotary Airlock Valve

- Transmission Sprockets

- Geared & Flexible Coupling

- Conveyor Parts

- Industrial Chain Coupling

- U Shear Mount

- Honey Comb Chain or Belt

- Half Gear Rigid Coupling

- Minimess Couplings

- Roto Cone Vacuum Dryer

- Rubber Expansion Bellows

- Wheel Flange

- Universal Joints

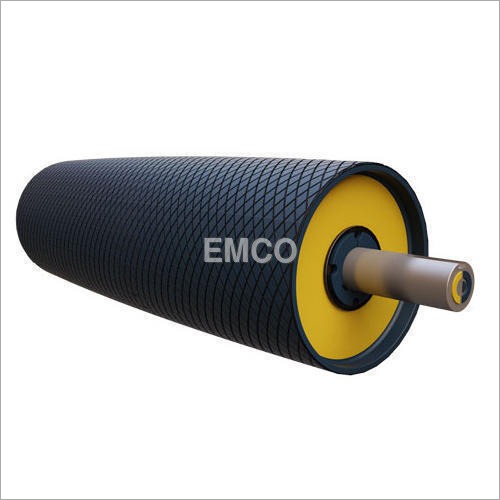

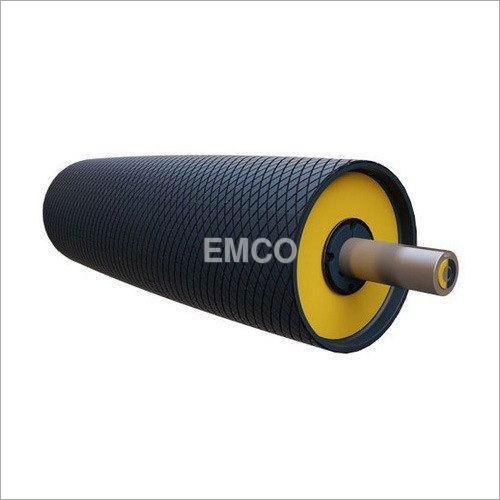

Carbon Steel Conveyor Pulleys

2500 INR/Piece

Product Details:

- Color Black

- Usage Conveyor pulley

- Product Type Conveyor Pulley

- Click to View more

X

Carbon Steel Conveyor Pulleys Price And Quantity

- 2500 INR/Piece

- 10 Piece

Carbon Steel Conveyor Pulleys Product Specifications

- Conveyor pulley

- Black

- Conveyor Pulley

Product Description

Backed by a team of experts, we have been a renowned manufacturer of Carbon Steel Conveyor Pulleys in the market. These are designed for use on belt conveyor systems as a means to redirect, drive, provide tension to, or help track the conveyor belt. It is not designed for the same application intent as conveyor rollers.

Carbon Steel Conveyor Pulley Specifications:

1. Material: Carbon Steel

2. Thickness: 150 mm

3. Material: Steel

4. Size: Customized Size

5. Color: Buyer's Requirements

Applications of Carbon Steel Conveyor Pulley:

1. Mining Industry: Carbon steel conveyor pulleys are widely used in mining operations for transporting bulk materials such as coal, ore, and minerals. They can withstand the harsh conditions of mining environments, including abrasive materials and heavy loads.

2. Aggregate and Construction: In the construction and aggregate industries, carbon steel conveyor pulleys are used to move sand, gravel, and other construction materials. They are essential components in conveyor systems that facilitate the efficient movement of these materials.

3. Manufacturing and Industrial Plants: Conveyor systems with carbon steel pulleys are commonly employed in manufacturing plants for handling various products during production processes. They are used for transporting materials between different stages of production lines.

4. Agriculture: Carbon steel conveyor pulleys find applications in agriculture for handling bulk materials like grains, seeds, and fertilizers. They are used in conveyor systems for loading, unloading, and transporting agricultural products within processing facilities.

5. Recycling Facilities: Recycling plants utilize conveyor systems with carbon steel pulleys to transport and sort recyclable materials such as paper, plastics, and metals. The robust nature of carbon steel makes it suitable for handling diverse recyclables.

6. Power Plants: Conveyor systems are integral to power plants for handling coal and other fuel materials. Carbon steel conveyor pulleys are well-suited for this application due to their strength and resistance to wear, even in high-temperature environments.

7. Ports and Terminals: Ports and terminals use conveyor systems with carbon steel pulleys for loading and unloading cargo from ships. These pulleys are essential for efficient and reliable material handling in busy port environments.

8. Bulk Material Handling: Carbon steel conveyor pulleys are commonly used in bulk material handling facilities such as bulk terminals and storage warehouses. They help move large quantities of materials efficiently and reliably.

9. Food Processing: In the food industry, carbon steel conveyor pulleys can be used in specific applications where corrosion resistance is not the primary concern. They are utilized for transporting bulk food items within processing plants.

10. Automotive Industry: Conveyor systems with carbon steel pulleys are employed in the automotive industry for handling components and parts during the manufacturing process. They facilitate the movement of materials between different production stages.

Carbon Steel Conveyor Pulley FAQ:

Q. What is a carbon steel conveyor pulley?

Ans: A carbon steel conveyor pulley is a component of a conveyor system used to support and guide the conveyor belt. It is typically made of carbon steel due to its strength and durability.

Q. Why choose carbon steel for conveyor pulleys?

Ans: Carbon steel is chosen for conveyor pulleys because it offers high strength, good wear resistance, and is cost-effective. It can withstand heavy loads and is suitable for various industrial applications.

Q. What are the key benefits of carbon steel conveyor pulleys?

Ans: The key benefits include high strength, durability, resistance to wear, and cost-effectiveness. Carbon steel pulleys are also suitable for a wide range of industrial environments.

Q. In which industries are carbon steel conveyor pulleys commonly used?

Ans: Carbon steel conveyor pulleys are commonly used in industries such as mining, construction, manufacturing, agriculture, recycling, power plants, ports and terminals, bulk material handling, food processing, and the automotive industry.

Q. What types of loads can carbon steel conveyor pulleys handle?

Ans: Carbon steel conveyor pulleys can handle heavy loads, making them suitable for transporting bulk materials such as coal, ore, aggregates, agricultural products, and more.

Q. Are carbon steel conveyor pulleys resistant to corrosion?

Ans: Carbon steel is not inherently corrosion-resistant. In environments where corrosion is a concern, additional coatings or treatments may be applied to enhance corrosion resistance.

Q. Can carbon steel conveyor pulleys be used in high-temperature environments?

Ans: Carbon steel has good heat resistance, and it can be used in applications with elevated temperatures. However, in extremely high-temperature environments, other materials with better heat resistance may be preferred.

Q. What factors should be considered when selecting a carbon steel conveyor pulley?

Ans: Factors to consider include the type of material being transported, environmental conditions, load capacity, belt speed, and the specific requirements of the application.

Q. Do carbon steel conveyor pulleys require maintenance?

Ans: Regular inspection and maintenance are recommended to ensure the proper functioning of conveyor pulleys. This may include checking for wear, alignment, and lubrication.

Q. Are there different types of carbon steel conveyor pulleys?

Ans: Yes, there are various types of carbon steel conveyor pulleys, including drive pulleys, tail pulleys, and bend pulleys. The specific type needed depends on the conveyor system's design and requirements.

Q. Can carbon steel conveyor pulleys be customized for specific applications?

Ans: Yes, manufacturers often offer customization options to meet the specific needs of different applications. This may include variations in size, design, and coating options.

Q. What are the typical maintenance practices for carbon steel conveyor pulleys?

Ans: Maintenance practices may include regular inspection for wear and damage, proper lubrication of bearings, and addressing any misalignment issues. Cleaning and removing debris from the pulleys are also common maintenance tasks.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free